How PCB Assembly Services Simplify Your Electronics Projects

In the rapidly evolving world of electronics, product development demands precision, efficiency, and reliability. Printed Circuit Board (PCB) assembly services play a crucial role in meeting these demands by streamlining the complex process of transforming electronic designs into functional products. Leveraging professional PCB assembly services can significantly simplify your electronics projects, reducing time-to-market, improving quality, and minimizing the risk of errors.

Understanding PCB Assembly and Its Importance

PCB assembly refers to the process of mounting and soldering electronic components onto a printed circuit board to create a working electronic device. This process includes the placement of surface-mount devices (SMDs) and through-hole components, followed by soldering and testing.

For engineers and designers, PCB assembly is a critical phase that bridges the gap between concept and reality. Proper assembly ensures electrical connectivity, mechanical stability, and optimal performance of the final product. Mistakes or inconsistencies during assembly can lead to product failures, increased costs, and delayed launches. Therefore, utilizing specialized PCB assembly services is essential for ensuring accuracy and efficiency.

Streamlining Complex Processes with Expert Services

One of the primary ways PCB assembly services simplify electronics projects is by managing the complexities inherent in the assembly process. Modern electronics often involve intricate designs with high component densities and a mixture of technologies. Handling such complexity in-house requires significant investment in equipment, skilled labor, and quality control systems.

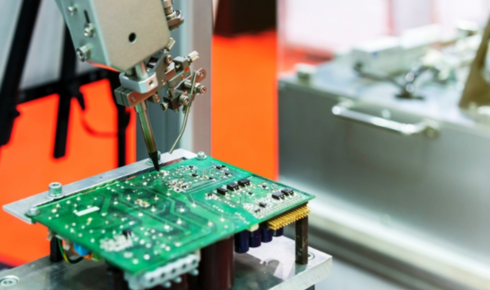

Professional PCB assembly providers offer advanced manufacturing capabilities, including automated pick-and-place machines, reflow soldering ovens, and inspection systems. These technologies enable precise component placement and reliable soldering, which are difficult to achieve manually. By outsourcing PCB assembly, project teams can leverage these resources without the overhead of maintaining their own manufacturing infrastructure.

Moreover, PCB assembly services follow standardized procedures and quality certifications, such as IPC standards, ensuring consistent product quality. This adherence to industry standards reduces the likelihood of defects and improves overall reliability, giving project managers peace of mind.

Reducing Time-to-Market and Costs

Speed is critical in electronics development. PCB assembly services help accelerate project timelines by consolidating multiple stages of production into a streamlined workflow. From sourcing components to final assembly and testing, professional services coordinate all steps efficiently.

By outsourcing PCB assembly, companies can avoid delays related to material procurement and production setup. Assembly providers typically maintain relationships with component suppliers and manage inventory, enabling faster turnaround times. This accelerated pace allows businesses to bring products to market more quickly, gaining a competitive advantage.

In addition to time savings, PCB assembly services can reduce overall project costs. The economies of scale enjoyed by assembly specialists lower per-unit costs, especially for medium to large production runs. Additionally, minimizing rework and defective units through professional assembly reduces waste and associated expenses.

Enhancing Design Flexibility and Innovation

Collaborating with PCB assembly services also fosters greater design flexibility. Assembly experts often provide valuable feedback during the design-for-manufacturing (DFM) stage, identifying potential assembly challenges and suggesting improvements. This proactive approach prevents costly redesigns and streamlines production.

By entrusting assembly to specialized providers, engineers can focus more on innovation and development rather than manufacturing logistics. This division of labor enhances productivity and allows teams to concentrate on refining product features and performance.

Furthermore, many PCB assembly services offer prototyping and small-batch runs, enabling rapid iteration during the development phase. This capability supports agile design processes and faster validation of new concepts.

Ensuring Quality Through Comprehensive Testing

Quality assurance is a cornerstone of successful electronics projects, and PCB assembly services incorporate rigorous testing procedures to guarantee performance. Common testing methods include automated optical inspection (AOI), X-ray inspection for solder joint integrity, and functional testing of assembled boards.

These comprehensive quality controls detect defects early, reducing the risk of faulty products reaching customers. High-quality assembly results in more reliable end products, which enhances brand reputation and customer satisfaction.

Conclusion

PCB assembly services are indispensable partners in simplifying electronics projects. By managing the complexities of component placement, soldering, and quality control, these services enable faster, more cost-effective, and reliable production. Leveraging expert PCB assembly not only accelerates time-to-market but also allows design teams to focus on innovation and product development. For any electronics project aiming for success, integrating professional PCB assembly services is a strategic investment that ensures precision, efficiency, and quality.